Project timeline

Construction of the new Sydney Fish Market is progressing to schedule, with large concrete pours now underway. Completed and ongoing activities include:

formwork and structural reinforcement installation

structural concrete pours

establishing jumpform structures

prefabrication works at Glebe Island including precast concrete

services installation.

Multiplex is working with the community to manage the impacts of construction work. Upcoming activities will focus on building the concrete structure and night works for the next stage of Bridge Road upgrade.

View the latest project update.

View the latest construction notification.

Dewater cofferdam

Basement structure

Tower crane installation

Start Bridge Road works

Bridge Road works continue

Building structure works continue

Bridge Road works continue

Building structure

Roof structure and canopy

Facade installation

Fitout works

Landscape and public domain works

Substation energisation

Fish and recreational wharves

Sea habitat installation

Complete public art

Construction of new Sydney Fish market complete

Work hours

Our standard approved working hours are 7am to 5.30pm. Monday to Friday, and 7.30am to 3.30pm on Saturdays.

Respite is the period within the working day where noisy activities, such as rock breaking, and rock hammering, will not be carried out to provide a break from the noise impacts. Noisy activities will occur between:

Monday to Friday 9am to 12pm and 1pm and 5 pm

Saturday 9am to 12pm

Managing construction noise and vibration

It is important that noise management strategies are implemented to not only reduce impact to the community, but also to our workers who are often working at the source of the noise or vibration where it is most impactful. Some construction activities are inherently noisy and generate vibration which cannot be avoided.

A Construction Noise and Vibration Management Plan has been prepared to understand potential noise and vibration impacts during construction. It identifies measures to implement to reduce and manage potential noise and vibration impacts.

Noise and vibration monitoring is occurring on site in line with the project’s Condition of Consent.

Air quality

Construction activities are guided by the new Sydney Fish Market Construction Air Quality and Dust Management Plan (CAQMP). Dust monitors are installed within the site and at three locations around the site.

Some of the dust mitigation measures implemented on site include:

intermittent wetting down of dust and loose materials

covering and wetting down of stockpiles

machine and vehicle wheels are washed before exiting site

increased measures during excessive winds and as required.

Concrete works

The first concrete slab at the new Sydney Fish Market site was laid in May 2023. The milestone is a significant achievement for the project and marks the official start to the building phase of the structure.

Starting with the basement level, which will be surrounded by water, over 3,800 cubic metres of concrete will be poured across the project. That’s equivalent to almost 14 Olympic swimming pools. Over the next 6 months, an average of 75 concrete mixing trucks will arrive to site on each pouring day.

It is expected that standard construction hours will not allow enough time to complete the finishing works for larger slabs. Approval has been granted to allow works to continue until 8pm on weekdays, when required.

Read the concrete structure fact sheet to find out more

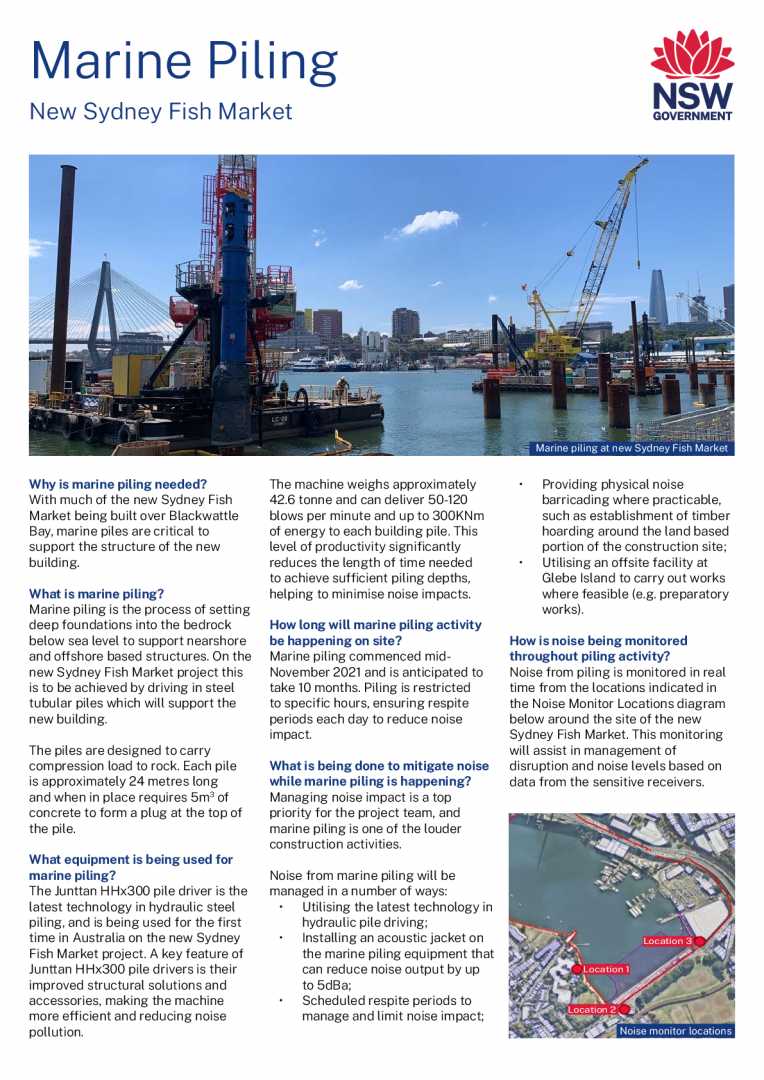

Marine piling

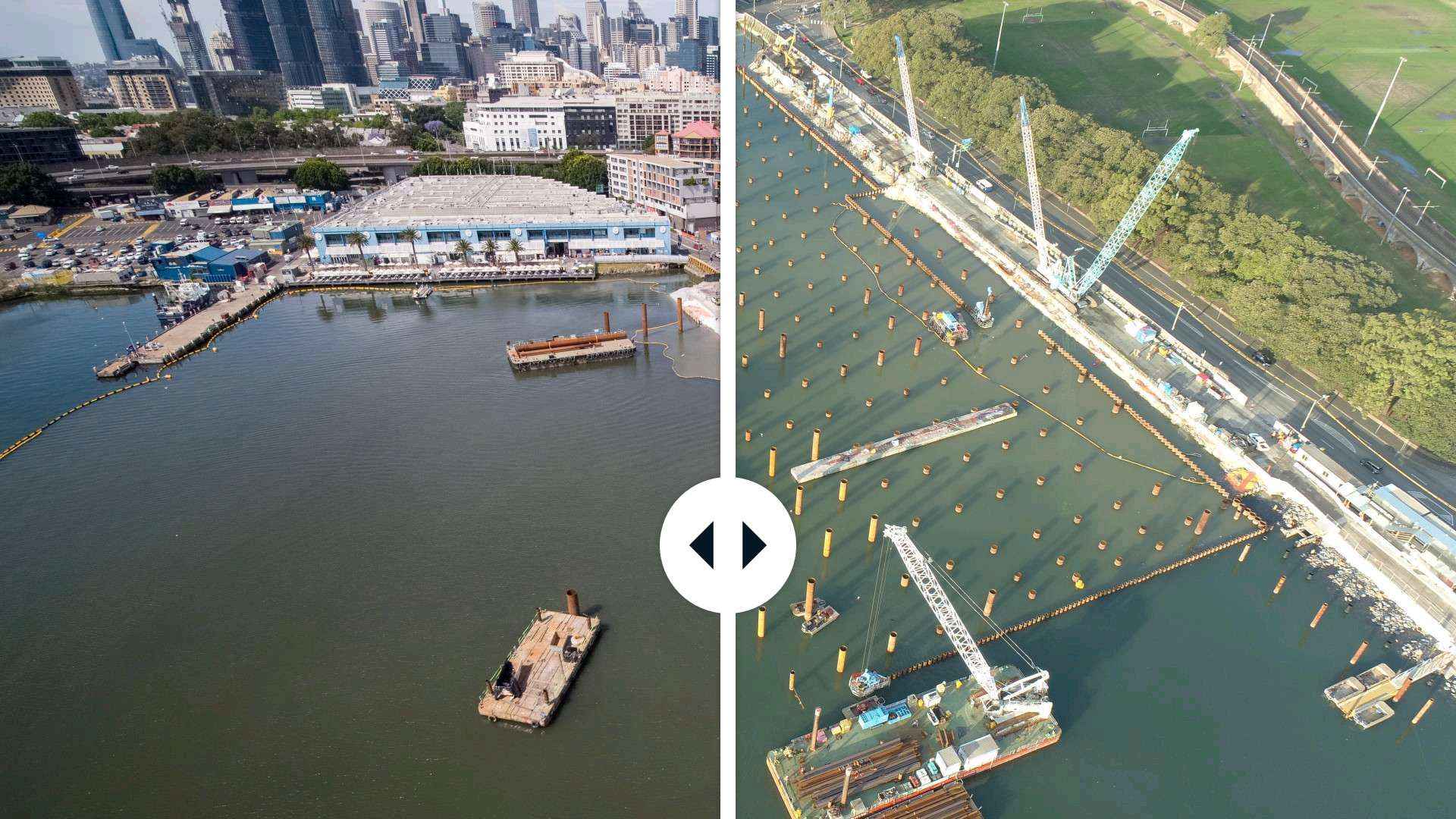

The new Sydney Fish market is being constructed over water and requires over 400 piles to support the new building structure, wharfs and adjacent promenade. Marine piling is expected to continue in 2023. The main building piles that will hold up the new structure were installed in 2022. The marine piling process is illustrated in the following diagrams (click to enlarge):

Image library and documents

Cofferdam

A cofferdam has been built within Blackwattle Bay. It creates a dry space to safely carry out the work of the main structure of the new Sydney Fish Market.

The cofferdam is a swimming pool-type structure, built around the perimeter of the new building.

The cofferdam is around 20,000 square meters (the size of about 4 football fields) in area.

Over 1,000 interconnected steel sheets and tubular piles, driven up to 22 metres into the seabed, are used to build the cofferdam wall.

The cofferdam is installed using Giken Japanese technology. The Giken is often referred to as the ‘silent piler’. It is typically quieter than most of the regular construction activities occurring on site.

Sheets are installed using a press-in method. Silent pilers utilise their own weight and reaction against

The draining of the cofferdam is an engineering feat and a major milestone for the project. It is one of the most exciting, unique, and highly technical elements of its construction.

Over 100 million litres of water have been pumped out (equivalent to 40 Olympic swimming pools) to drain the cofferdam to a level around 4 metres below sea level.

De-watering took 14 days and was undertaken using 9 barge-mounted pumps.

A suitable base within the cofferdam will be set up to construct the basement and floors of the new building.